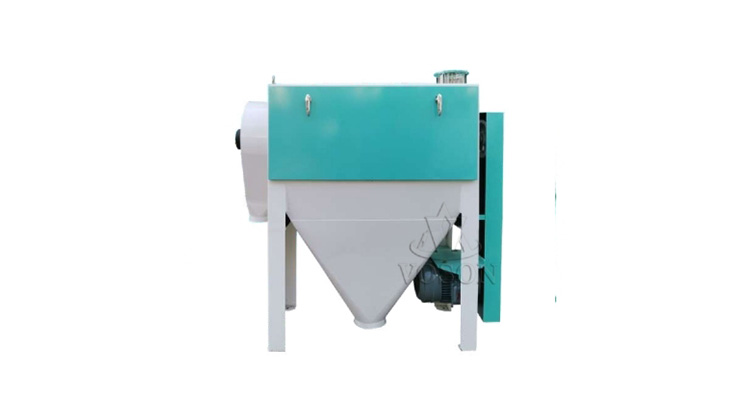

Horizontal bran threshing machine

- Capacity: 1-3TPH

- Production:

Extract the flour adhered to the tobacco skin, reduce the powder content of the tobacco skin, and improve the powder extraction rate.

Extract the flour adhered to the tobacco skin, reduce the powder content of the tobacco skin, and improve the powder extraction rate.

Extract the flour adhered to the tobacco skin, reduce the powder content of the tobacco skin, and improve the powder extraction rate.

1、Beat and push with a zigzag beater for higher flour yields;

2、Dynamically balanced rotor to ensure stable operation;

3、Stainless steel diamond-shaped cylinder, sufficient classification and high efficiency;

Below is the parameters of one of our options, feel free to contact for more details if you are interested in our product!

| Type | Sieve Roller | Speed(r/min) | Power(kw) | Capacity(t/h) | Wight(kg) | Size(mm) | |

| Diameter(mm) | Length(mm) | ||||||

| FPDW30*1 | Φ300 | 800 | 1300-1600 | 2.2 | 0.9-1.0 | 320 | 1270*480*1330 |

| FPDW30*2 | Φ300 | 800 | 1300-1600 | 2.2*2 | 1.8-2.0 | 640 | 1270*960*1330 |

| FPDW45*1 | Φ450 | 1100 | 1000-1100 | 5.5 | 1.3-1.5 | 500 | 1700*650*1620 |

| FPDW45*2 | Φ450 | 1100 | 1000-1100 | 5.5*2 | 2.6-3.0 | 1000 | 1700*1300*1620 |

Maize flour processing steps can be divided into 5 sections: cleaning, conditioning, degerminating, milling and sifting, packing.

During cleaning, first use a vibrating grading sieve or a primary cleaning sieve to remove impurities such as corn stalks, sand, and large stones.

Generally, the combined cleaning screen are used for small scale maize milling machine, such as 5-20 tons per day maize mill.

Then, there is a gravity grading screen is also a stoner, which cleans the small stones of corn seeds again to ensure the cleanliness of the raw materials. The principle is to use the different weights of impurities and maize. And for the large capacity maize processing line, there are vibrating screen and gravity classifier, even magnetic separator. Get Details

The purpose of using a moisture-proof device to adjust corn is to reduce the binding force between corn skin and endosperm, reduce endosperm strength, and be more conducive to grinding. Get Details

The purpose of peeling and degerming of corn is to obtain more products suitable for different food requirements. However, there are also many nutrients in corn husks and germs, such as cellulose, and peeling the husks means that we lose some of them. Get Details

The processed raw materials are ready to enter roller mills. Through the reciprocating grinding of the milling machine, the corn is grounded into flour. The roller mills have divided into two kinds of types:

Like the cleaning machine, we manufacture various of milling machine, and the right one will be applied in the small scale maize meal milling plant, for example, 10t posho milling machine, 20t maize milling machine, and 30tpd maize flour milling machine.

The left one has a large capacity of milling, so it's applied in industrial and commercial maize milling plant, such as 100-500t maize milling plant. Get Details

Milled maize will be sieved with high square, a double bin sieve, or a single square sieve to obtain maize meal and corn grits of different fineness. And the rest of not passed though the sieve will be milled again.

The packaging machines are divided into manual and automatic. If your business is relatively small, an electronic scale and a sewing machine are enough. If your production scale is large, then the automatic baler will be your assistant and save a lot of workers, higher efficiency.

There are other kinds of packaging machine that is more affordable for you to choose. Get Details

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one day. Please feel free to contact us!