How to design a 250ton wheat flour mill

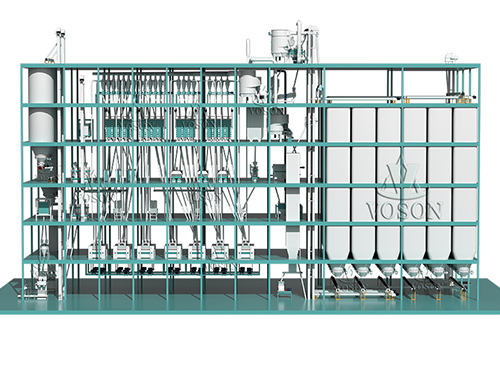

The 200ton/d wheat flour milling plant is a kind of multistory type seeds milling line. It consists of high square plansifter, pneumatic flour mill machine, purifier, etc. to realize advanced flour milling technology. It usually needs 4-6 floors (also can be designed into a steel structure) for installing the complete wheat flour plant. The whole plant is durable to use, easy to operate and maintain, and has high productivity and flour extraction rate. Therefore, this wheat flour mill plant can be used to produce different grade wheat flour as well as special flour. (Related Articles:250ton wheat flour mill)

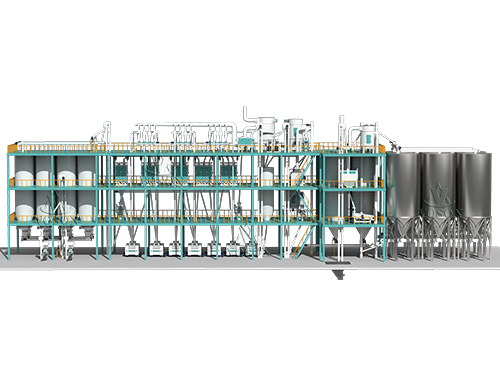

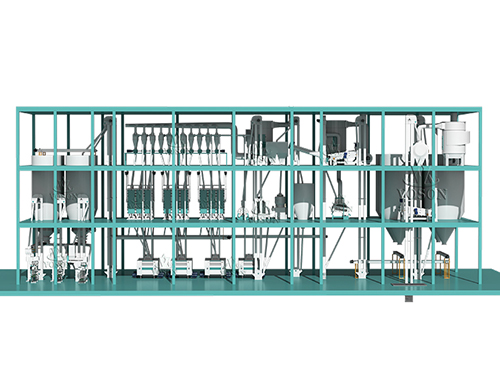

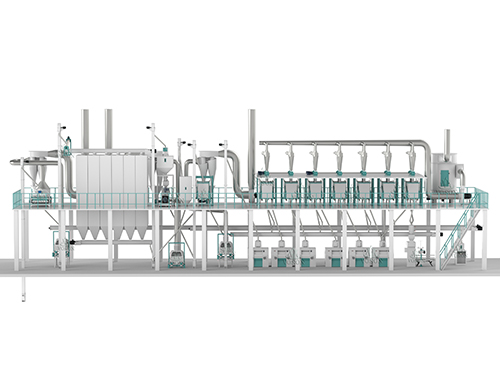

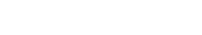

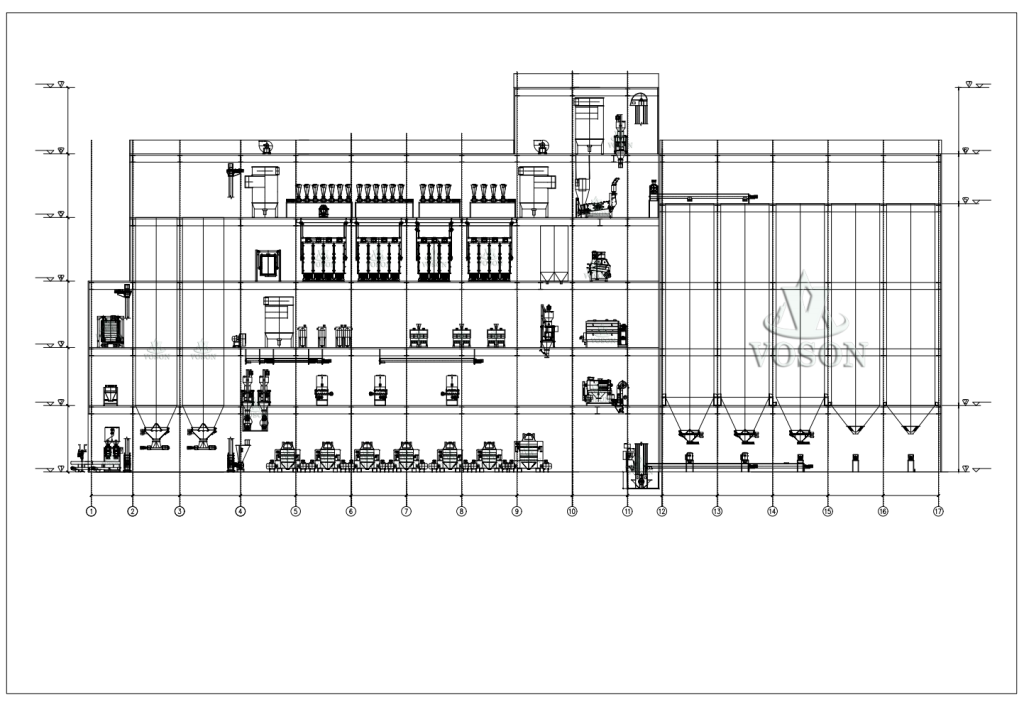

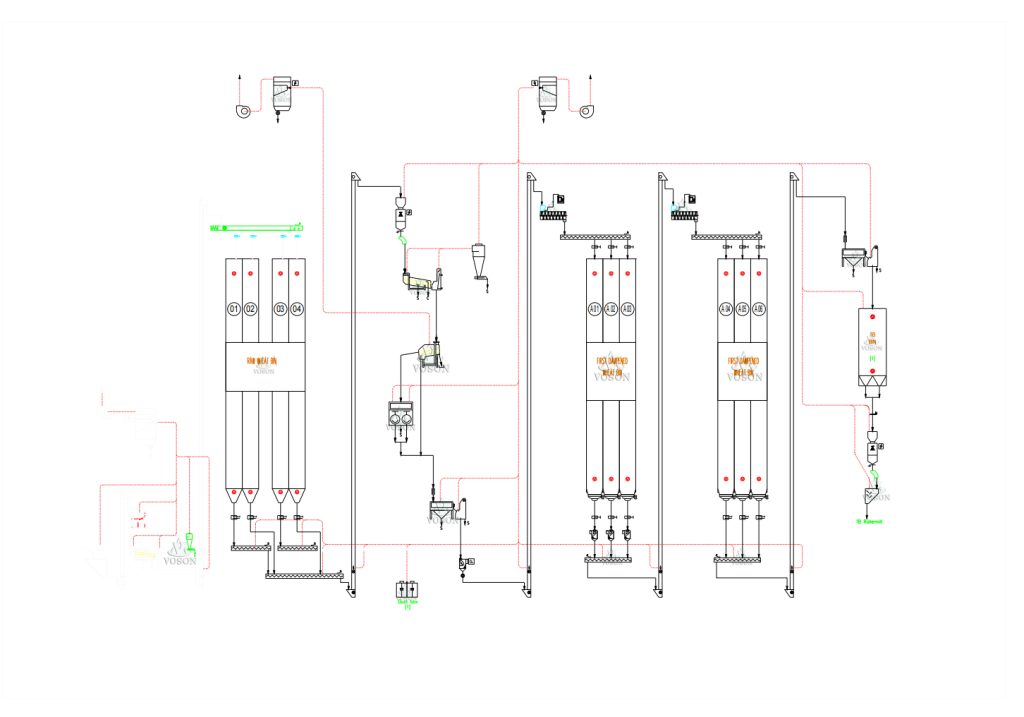

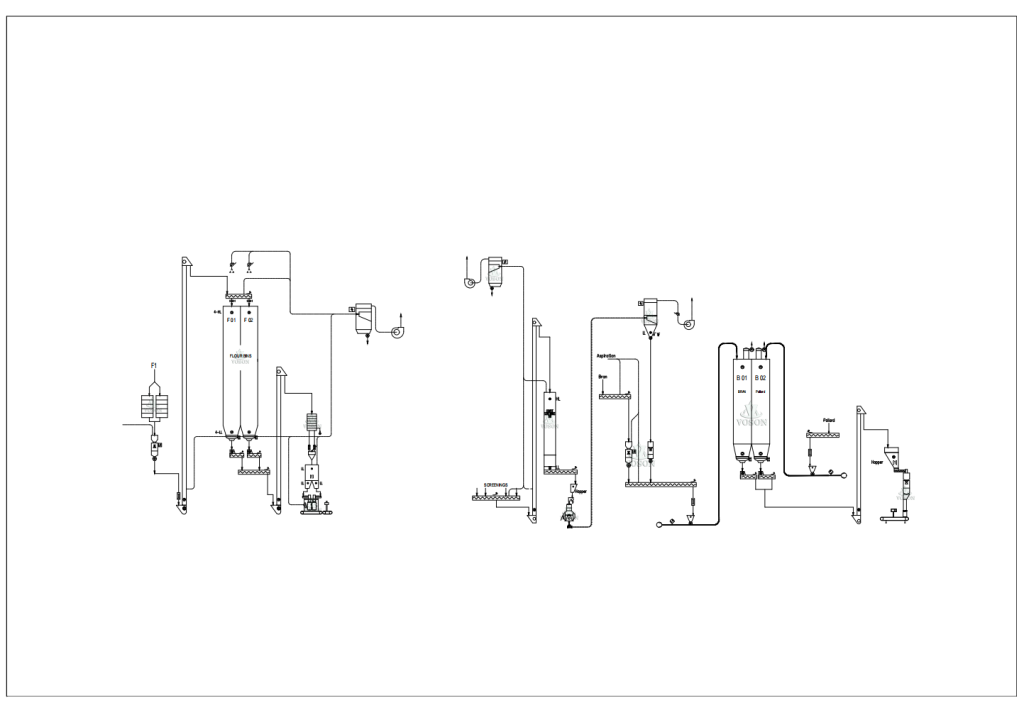

Equipment layout of 250 tons wheat mill

Designing the layout and process optimization for a 250-ton wheat milling plant can be divided into the following key steps:

Receiving Area: Set up a wheat receiving area with unloading hoppers and conveyors to transport wheat to the cleaning equipment.

Cleaning Equipment: Install cleaning devices such as sieves and air separators to remove impurities.

Milling Area: Configure milling equipment, including:

Mills (such as roller mills or hammer mills)

Milling separators

Classification and Packaging Area:

Set up screening machines to separate flour of different fineness.

Packaging machines for packing and shipping finished products.

Types of Wheat flour can be processed

Pursuing suitable wheat flour milling machinery for your business is important. We have projects, and you can get advice and free craft designs from us.

There are many types of flour, such as bread flour, whole wheat flour, cake flour etc. You can contact our engineers directly, they will tell you how to choose the right cost-effective and high-quality flour processing equipment. Hope to give you some guidance and advice on your business plan.

In VOSON, we have a full range of wheat milling machine and production line solutions, from 30-50 tons per day small scale wheat grinding mills to 100-500T large scale commercial wheat milling plants equipment, all that is available. Get Deatails

This layout and process can help enhance the efficiency and quality of the milling plant. It needs to be tailored to the specific area of the plant and the models of the equipment used. Do you have any specific requirements or details you’d like to discuss further?Contact Us