Electric vs Diesel Maize Milling Machines – Which is Better for Your Business?

Maize milling machines are essential equipment in grain processing, widely used in both small-scale and large-scale maize flour production. Choosing between an electric and a diesel-powered maize milling machine depends on various factors, including power availability, operational costs, efficiency, and intended usage. This article explores the differences between electric and diesel maize milling machines to help you make an informed decision.

1. Power Source and Reliability of Maize Milling Machines

Electric Maize Milling Machines: These maize milling machines run on electricity and are ideal for locations with a stable power supply. They offer consistent performance with minimal fluctuations.

Diesel Maize Milling Machines: These machines use diesel fuel and are best suited for areas where electricity is unreliable or unavailable. They provide independence from grid power and are particularly useful in remote locations.

2. Running Costs and Efficiency of Electric vs. Diesel Maize Mills

Electric Models: Generally have lower operating expenses, as electricity is often cheaper than fuel. They also require less frequent maintenance.

Diesel Models: Higher fuel costs and frequent servicing, such as oil changes and engine maintenance, can increase long-term expenses.

3. Performance and Productivity Comparison of Maize Milling

Electric Units: Deliver consistent efficiency and smooth operation without concerns about fuel shortages or engine wear.

Diesel Units: Rugged and capable but may experience energy conversion losses and more mechanical wear over time.

4. Maintenance and Durability of Electric and Diesel Maize Mills

Electric Mills: Require minimal upkeep, with fewer mechanical parts subject to wear and tear.

Diesel Mills: Need regular servicing, including engine care and fuel filter changes, but are built for durability in harsh conditions.

5. Environmental Considerations for Maize Milling Machines

Electric Maize Milling Machines: More environmentally friendly as they do not produce emissions. If powered by renewable energy sources, they are a sustainable option.

Diesel Maize Milling Machines: Emit carbon dioxide and other pollutants, making them less eco-friendly. Noise pollution is also a factor to consider.

6. Mobility and Flexibility of Electric and Diesel Maize Milling Machines

Electric Maize Mills: Less mobile, as they need a direct power source, making them ideal for fixed milling stations.

Diesel Maize Mills: Highly portable, allowing use in remote locations where electricity is unavailable.

Best Maize Flour Milling Machine for Sale

Choose an electric maize milling machine if you have stable electricity, want lower operational costs, and prefer an eco-conscious solution.

Opt for a diesel milling machine if you need portability, operate in off-grid areas, or want power autonomy.

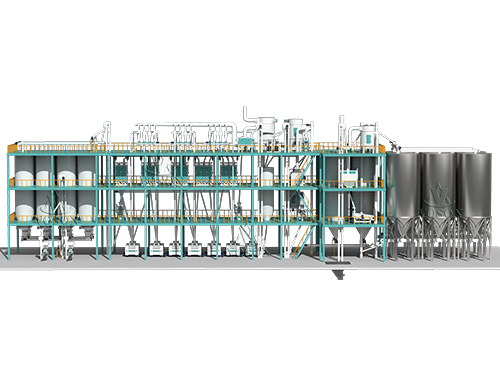

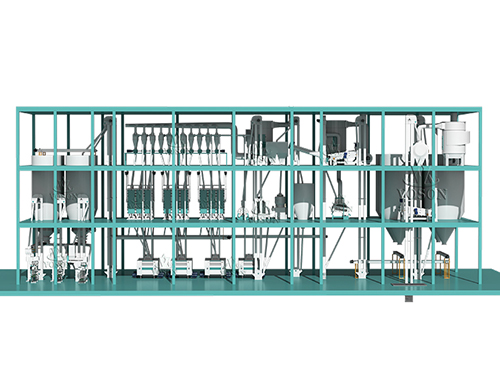

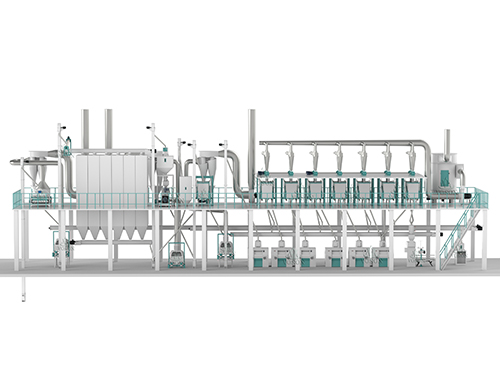

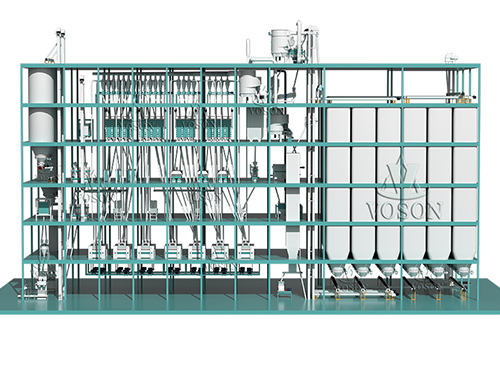

Explore Premium Milling Solutions with Voson Machinery. At Voson Machinery, we offer high-quality electric and diesel maize milling machines tailored to diverse business needs. Contact us today for expert consultation and find the best solution for your operation!We have designed several maize flour milling machines that is very popular. With compact steel structure, easy installation and operation, very suitable for you to start a maize milling machine.

In VOSON, we have a full range of corn milling machine and production line solutions, from 30-50 tons per day small scale maize grinding mills to 100-500T large scale commercial maize milling plants equipment, all that is available. Get Deatails