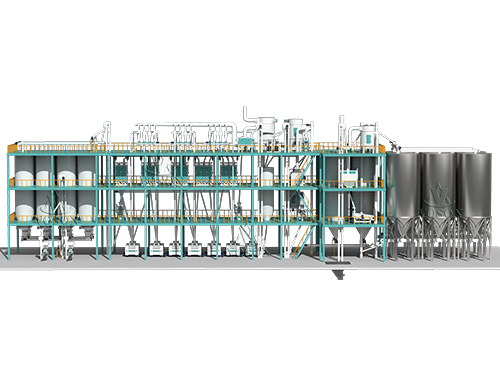

Instant Nutritional Powder Production Line

This project showcases a Instant Nutritional Powder Production Line designed for processing corn, wheat, soybean, sorghum and other seeds into high-quality pregelatinized flour.

The production line adopts controlled thermal pre-gelatinization combined with precision milling technology to produce flour with excellent instant solubility, improved digestibility and stable particle size.

With a flexible production capacity ranging from 10 to 100 tons per day (TPD), this turnkey grain flour milling project is suitable for small, medium and industrial-scale food processing plants.

Project Background – Instant Grain Flour Milling Solution

Traditional grain flour produced by conventional milling lines requires further cooking before consumption. However, the increasing demand for instant grain flour, nutrition powder and functional food ingredients has driven the market toward pregelatinized flour.

Pregelatinized flour is produced by applying thermal treatment to grains, resulting in partial starch gelatinization. This process significantly improves water absorption, rehydration performance and digestibility, while enhancing flavor and product stability.

This Instant grain flour milling solution was developed to help customers efficiently process multiple grains into value-added instant flour products.

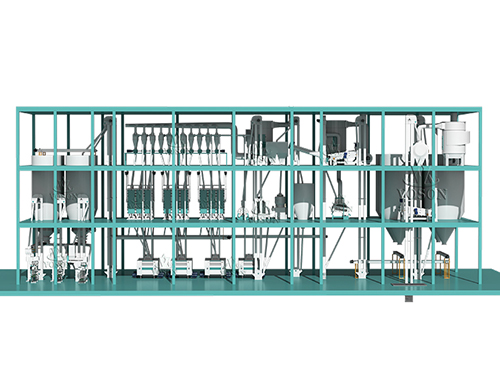

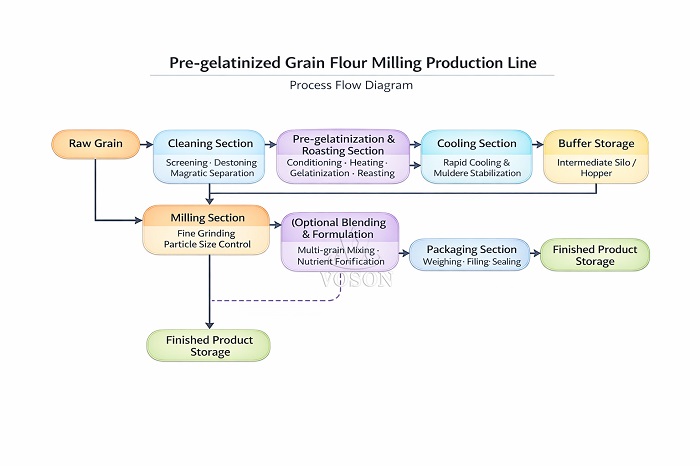

Processing Flow of Instant Nutritional Flour Production Line

1、Raw Grain Cleaning

The raw grains first pass through a grain cleaning system equipped with vibrating screen, destoner, and magnetic separator.

This stage removes impurities such as dust, stones, and metal contaminants, ensuring clean and safe raw materials before thermal processing.

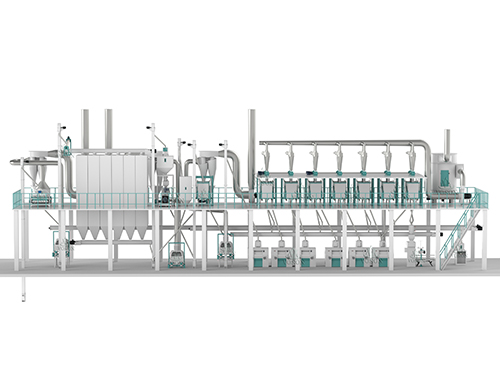

2、Pre-gelatinization & Roasting

After cleaning, the grains enter a continuous roasting or steam-roasting system for thermal treatment.

During this process, the grains are fully cooked, natural aroma is released, starch is partially gelatinized, and cell structures are broken down, significantly improving digestibility and nutrient absorption.

3、Cooling & Buffer Storage

The pre-gelatinized grains are rapidly cooled through a cooling system to prevent excessive moisture loss or over-gelatinization.

After cooling, the grains are transferred to buffer silos to stabilize material flow and ensure consistent milling performance.

4、Milling & Grinding

The cooled pre-gelatinized grains are processed by multi-stage grinding machines or roller mills, producing uniform flour.

The flour fineness can be flexibly adjusted according to product requirements, ranging from coarse cereal flour to fine instant powder.

5、Screening & Classification

Vibrating screens or air classification systems are used to grade the flour.

This step ensures consistent particle size distribution, removes oversized particles, and guarantees a smooth and uniform final product.

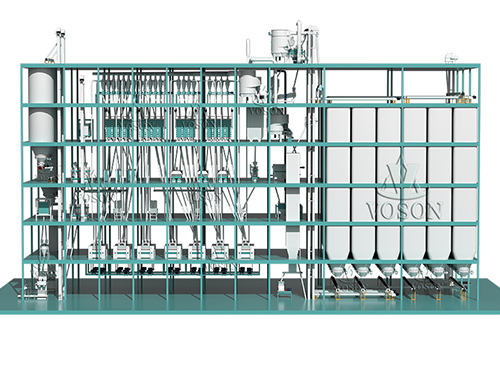

6、Blending & Formulation (Optional)

For customized products, different grain flours can be blended, or nutritional ingredients such as vitamins and mineral premixes can be added to meet specific formulation requirements.

7、Automatic Packaging

The finished pre-gelatinized flour is packed using automatic weighing and packaging machines, ensuring accurate dosing, moisture protection, airtight sealing, and convenient transportation.

Applications of Pre-gelatinized Grain Flour

The production line is widely used in the following sectors:

- Instant Cereal & Ready-to-Eat Grain Powder

Such as pre-gelatinized corn flour, wheat flour, soybean flour, and mixed grain powders that can be consumed directly by adding hot water. - Infant Food & Elderly Nutrition Products

Pre-gelatinization improves starch digestibility and destroys anti-nutritional factors, making the flour suitable for sensitive consumer groups. - Functional & Health Food Industry

Including whole grain flour, sorghum flour, low-GI formulations, and customized nutritional powders for domestic and international markets.

Compared with conventional grain milling lines, this Pre-gelatinized Grain Flour Milling Production Line offers higher product value, broader application range, and stronger market adaptability, making it an ideal choice for food processing enterprises targeting instant and functional grain products.