Millet Dehulling Machine

- Capacity: 500–2000 kg/h

- Production: Millet

The millet dehulling machine from Henan Voson Grain Engineering Machinery Co., Ltd. is a professional grain shelling equipment used to remove husks from various types of millet.

The millet dehulling machine from Henan Voson Grain Engineering Machinery Co., Ltd. is a professional grain shelling equipment used to remove husks from various types of millet.

The millet dehulling machine from Henan Voson Grain Engineering Machinery Co., Ltd. is a professional grain shelling equipment used to remove husks from various types of millet. Designed with abrasive and friction-based dehulling technology, this machine ensures efficient separation of the husk while preserving the edible kernel.

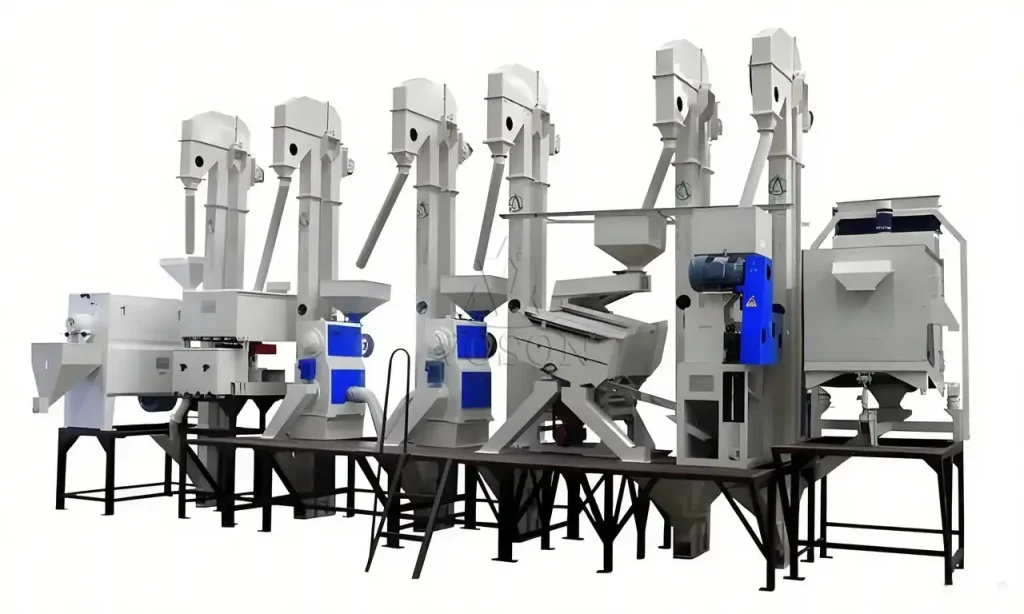

Widely used in small millet processing plants and industrial grain production lines, the VS Series millet husk remover provides consistent performance, minimal kernel breakage, and clean product output. It supports standalone operation or can be integrated into full grain processing systems.

The VOSON millet dehulling machine operates on a friction-based dehulling mechanism:

Raw millet is fed into the dehulling chamber through a regulated feeding system.

Inside the chamber, abrasive rollers or emery-coated cylinders apply controlled pressure to separate the husk.

Air suction or vibration helps to remove the loosened husks and clean the kernel surface.

Peeled millet is discharged through a collection outlet, while husk is extracted separately.

| Model | Capacity (kg/h) | Power (kW) | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|

| VS-MDH100 | 500 – 800 | 7.5 | 1200 × 600 × 1300 | 200 |

| VS-MDH150 | 800 – 1200 | 11 | 1350 × 700 × 1450 | 280 |

| VS-MDH200 | 1200 – 2000 | 15 – 18.5 | 1500 × 800 × 1600 | 360 |

Note: Performance may vary depending on millet type, size, and moisture level.

Efficient Husk Removal for Various Millet Types

Suitable for foxtail millet, proso millet, barnyard millet, and other small-seed grains.

High Kernel Recovery Rate

Advanced structure minimizes grain breakage and ensures a high yield of intact kernels.

Compact, Durable & Low Maintenance

Industrial-grade build quality ensures long service life and reliable operation.

Energy-Efficient Performance

Optimized power-to-output ratio helps save operational costs.

Customizable to Different Processing Needs

Adjustable dehulling pressure and speed to handle different grain sizes and moisture levels.

Trusted by Grain Processors Worldwide

Voson millet dehulling machines have been exported to over 30 countries.

Q1: Can this machine handle all millet varieties?

A: Yes, it is suitable for foxtail millet, proso millet, barnyard millet, pearl millet, etc.

Q2: Does it require pre-conditioning of the grains?

A: Slight moisture conditioning (12%–14%) is recommended for optimal husk removal.

Q3: Can this machine be used for other grains?

A: While optimized for millet, it can also process similar small grains like quinoa and buckwheat with adjustments.

Q4: Is the dehulling system fully enclosed?

A: Yes, the structure is enclosed to prevent dust and ensure clean operation.

Henan Voson Grain Engineering Machinery Co., Ltd. specializes in grain processing equipment, including millet dehullers, wheat peeling machines, corn flour mills, and complete turnkey projects. With more than 20 years of industry experience and project coverage across Asia, Africa, and Eastern Europe, Voson delivers reliable and efficient grain engineering solutions for global clients.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one day. Please feel free to contact us!