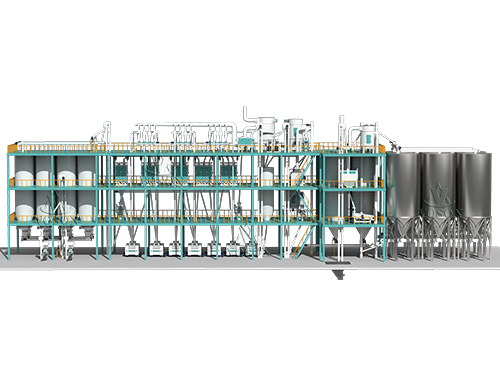

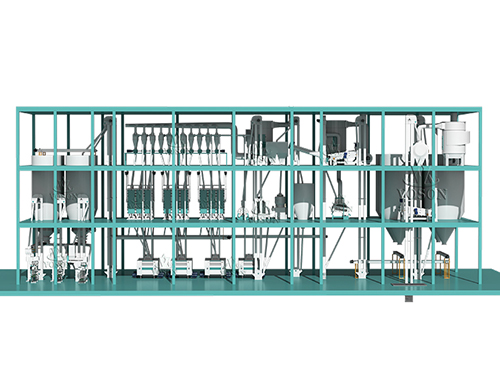

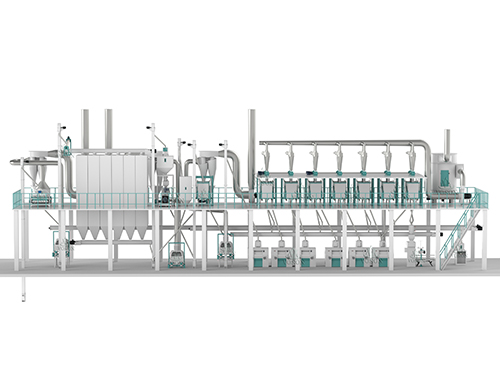

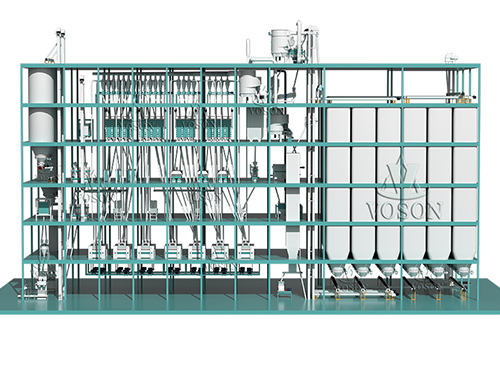

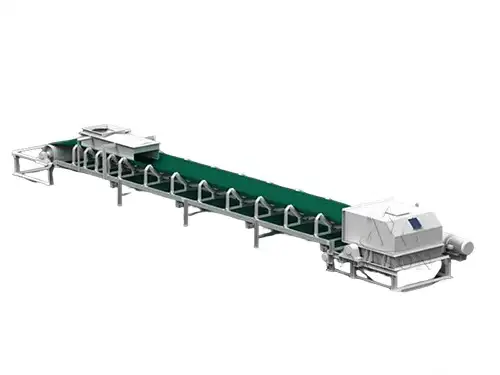

Air Cushion Belt Conveyor for Flour Milling & Grain Handling

The Air Cushion Belt Conveyor (ACBC) is an advanced bulk material handling system widely applied in modern flour milling plants and grain handling engineering projects. Unlike traditional idler belt conveyors, this system adopts air-supported conveying technology, forming a stable air film between the conveyor belt and the carrying pan.

By eliminating direct mechanical contact between the belt and supporting components, the air cushion belt conveyor significantly reduces friction, power consumption, and maintenance requirements. As a result, it has become an ideal conveying solution for wheat, maize, soybeans, and powder materials in large-capacity flour mills, grain storage facilities, and turnkey grain processing projects.

Working Principle & Main Structure

2.1 Air-Supported Conveying Principle

During operation, low-pressure air is continuously supplied into the air box beneath the belt. The air flows through precisely distributed throttling orifices, forming a uniform air cushion that lifts the conveyor belt by approximately 0.05–0.15 mm. This thin air layer allows the belt to run smoothly with extremely low resistance, even under heavy load conditions.

2.2 Key Structural Components

Air Box & Carrying Pan

Manufactured from high-strength steel plates, the trough-shaped pan is designed to ensure uniform air pressure distribution. Its structural rigidity guarantees stable belt support during long-term continuous operation in flour milling environments.

Air Supply System

Independent centrifugal fans deliver stable airflow into the plenum chamber. The system maintains sufficient pressure to support both the belt and conveyed material, ensuring reliable performance under varying capacities.

Fully Enclosed Sealing Cover

The modular enclosed design effectively prevents dust leakage during grain conveying. This feature is particularly important for flour mills, where dust control, hygiene, and food-grade safety standards must be strictly maintained.

Technical Comparison – Air Cushion vs. Traditional Idler Belt Conveyor

| Comparison Item | Traditional Idler Conveyor | Air Cushion Belt Conveyor | Engineering Benefit |

|---|---|---|---|

| Friction Coefficient (f) | 0.022 – 0.030 | 0.001 – 0.005 | Over 80% resistance reduction |

| Power Consumption | High | 15–30% lower | Long-term energy savings |

| Material Breakage | Grain vibration & impact | Smooth, vibration-free | Protects grain integrity |

| Maintenance Frequency | Frequent roller replacement | Minimal maintenance | Reduced downtime & labor |

| Dust Control | Difficult to fully seal | Fully enclosed structure | Cleaner flour mill environment |

| Belt Service Life | Roller wear impact | 2–3× longer belt life | Lower operating cost |

This comparison clearly demonstrates why air cushion belt conveyors are increasingly selected in large-scale flour mill and grain engineering projects.

Engineering Advantages in Flour Mill Projects

1. Energy-Saving Operation

By removing hundreds of idlers and associated rolling resistance, the air cushion belt conveyor operates with significantly lower power demand. This advantage becomes particularly evident in long-distance conveying systems commonly used in flour mills and grain terminals.

2. Low Grain Breakage Rate

The conveyor belt runs on a continuous air film without vibration. Grains remain stable on the belt surface, avoiding the repeated impacts caused by traditional rollers. This makes the system especially suitable for wheat and maize handling, where grain integrity directly affects milling quality.

3. Minimal Maintenance Requirement

The simplified mechanical structure eliminates lubrication points and roller wear parts. Routine maintenance is largely limited to air fans and belt inspection, making the system nearly maintenance-free during normal operation.

4. High Capacity & Operational Stability

Air cushion belt conveyors maintain stable performance at high conveying speeds and large capacities. They are well suited for continuous raw grain intake, silo-to-mill transfer, and finished product conveying in modern flour milling plants.

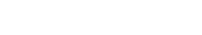

Typical Applications in Grain & Bulk Material Handling

In engineering practice, air cushion belt conveyors are most widely used in flour milling and grain handling systems, particularly for raw grain intake, long-distance conveying between silos and mills, and enclosed transfer sections with strict dust control requirements.

In addition to grain processing, air cushion belt conveyors are also applied in bulk material conveying for industries such as mining, cement, power generation, and chemical processing, where stable operation, low maintenance, and enclosed conveying are essential for continuous production.