Key Factors to Consider When Buying Wheat and Corn Milling Machines

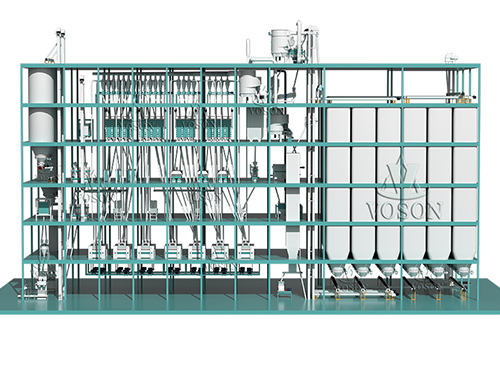

Investing in a wheat or corn milling machine is a critical decision for any flour milling business. The right machine can significantly improve flour quality, operational efficiency, and long-term profitability. However, selecting the best equipment requires careful consideration of several factors. Drawing on Voson’s extensive experience in designing and supplying milling solutions worldwide, this guide highlights the essential points to consider when choosing wheat and corn milling machines.

Determine Your Production Capacity Requirements

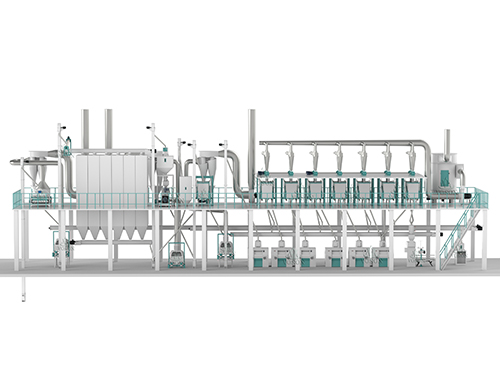

The first step is to define your production needs. Milling machines come in a wide range of capacities, from small laboratory units to large-scale industrial systems capable of processing hundreds of tons per day. Factors to evaluate include:

- Expected daily output in tons

- Peak operational hours per day

- Types of grains you intend to process, such as wheat, corn, or a combination

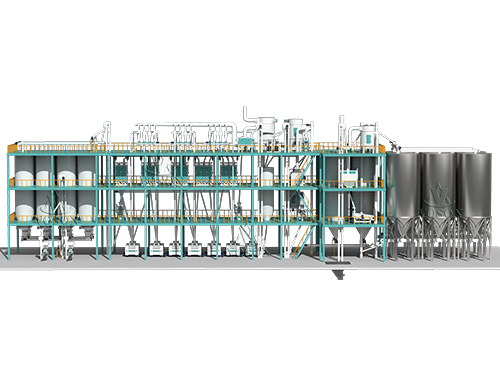

Selecting a machine that aligns with your production requirements ensures stable operation, reduces downtime, and maximizes the return on investment. Voson offers milling machines suitable for capacities ranging from small pilot-scale units to fully industrial production lines.

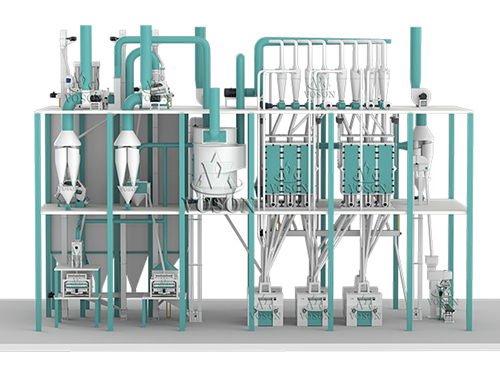

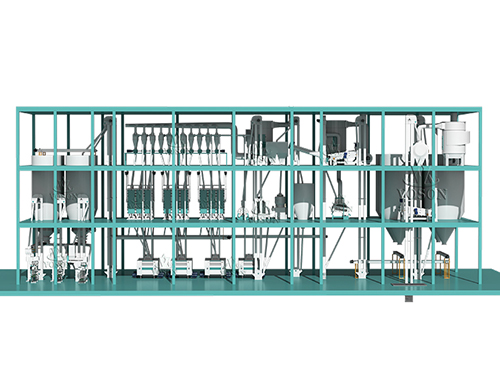

Choose the Right Milling Technology

The type of milling machine you choose affects the final flour quality and efficiency. For wheat milling, roller mills are preferred for producing fine and uniform flour. Corn milling can utilize hammer mills, roller mills, or a combination depending on the desired texture and end product. Key points include:

- Roller mills: High precision, consistent flour particle size, and energy efficiency

- Hammer mills: Flexible for coarse or medium grind, suitable for diverse grains

- Integrated milling lines: Combining different technologies for multi-grain processing

Voson’s milling machines employ advanced roller and hammer milling technologies, ensuring reliable operation and high-quality flour production.

Evaluate Energy Efficiency and Operating Costs

Energy consumption is a major factor in the long-term cost of running a flour mill. Modern milling machines are designed to reduce power usage without compromising performance. Consider machines with:

- Optimized motors and drive systems

- Low energy consumption per ton of grain processed

- Environmentally friendly features to meet sustainability standards

Investing in energy-efficient equipment reduces operational costs and supports environmentally responsible production.

After-Sales Support and Turnkey Solutions

Reliable technical support is crucial for minimizing downtime and maintaining production efficiency. Consider suppliers that offer:

- Complete turnkey solutions, including design, installation, and commissioning

- Training and ongoing technical assistance

- Availability of spare parts and maintenance guidance

Voson provides end-to-end solutions, from pre-sale design to post-sale support, ensuring customers achieve optimal milling performance.

Selecting the right wheat milling machine or maize milling machine involves more than just comparing prices. Capacity, milling technology, energy efficiency, grain pre-treatment, automation, durability, and after-sales support all play a critical role. By choosing a trusted supplier like Voson, you gain not only high-performance equipment but also professional guidance to ensure smooth operation and long-term success in your milling business.