Efficient 20TPD Maize Flour Milling Plant in Nigeria | Turnkey Project by Voson

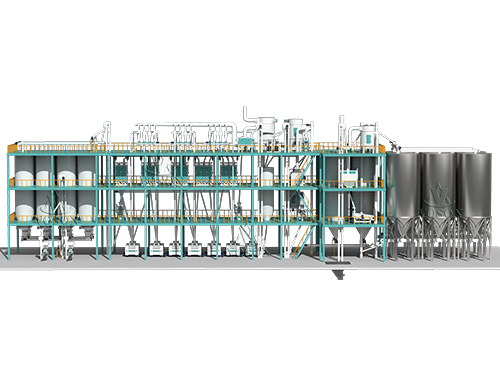

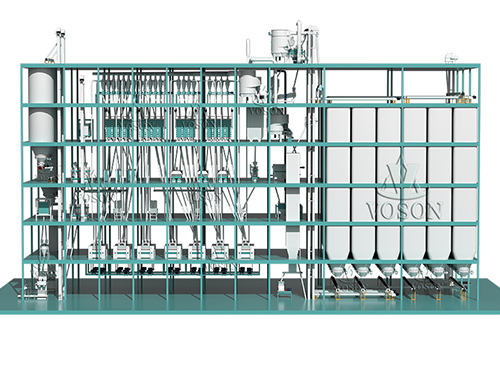

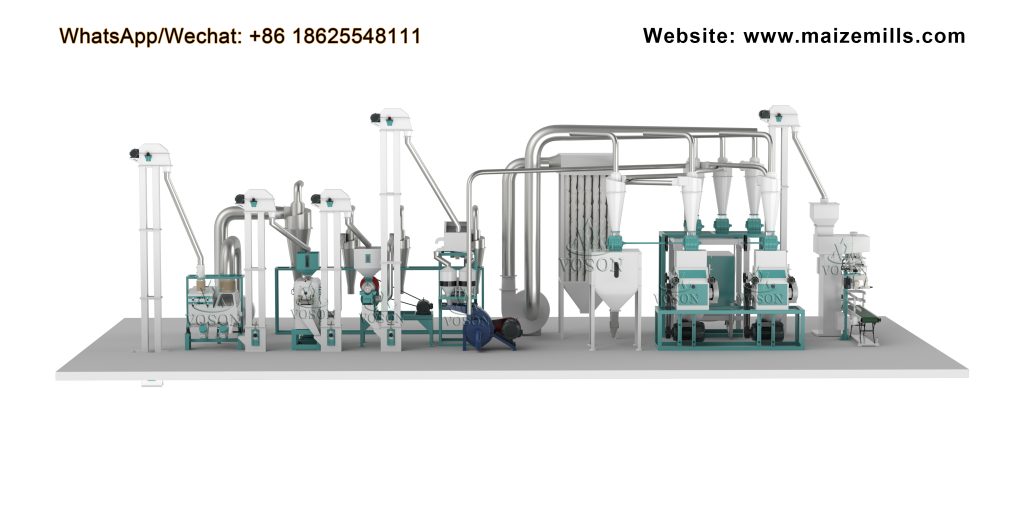

Voson successfully delivered a 20 tons per day maize flour milling plant in Kaduna, Nigeria. This compact, efficient, and fully automated line provides a turnkey solution tailored for the West African maize processing industry.This 20TPD Nigeria maize flour mill designed and installed by Voson, the project integrates cleaning, degerming, milling, and packaging into a streamlined production flow.

The client, a regional maize trader and food distributor, aimed to enter the maize flour market by investing in a reliable, low-cost plant with stable performance. Voson provided professional design, local customization, and on-site services—key factors in winning the project.

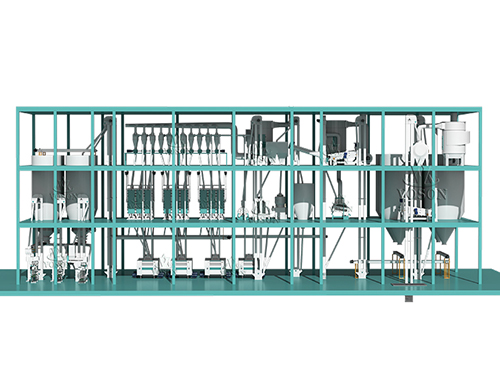

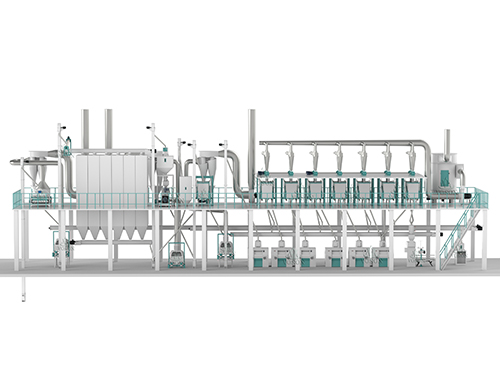

Plant Design & Core Equipment of the 20TPD Maize Milling Line

This maize flour processing line was customized for local grain varieties and includes:

1、Cleaning Equipment: Vibrating screen, destoner, magnetic separator

2、Degermination System: Maize polisher, advanced degerminator

3、Grinding & Milling: Roller mills, plansifter

4、Flour Handling: Dust-free bagging machine, cyclone dust collector

The setup fits within a single-story workshop and is optimized for energy efficiency and easy maintenance.

Why Choose Voson: Turnkey Maize Milling Project Expert

Voson stood out due to:

1、End-to-end engineering support (design, equipment, installation, training)

2、Equipment tailored for Nigerian maize conditions

3、Competitive price-performance ratio

4、Rapid installation (within 40 days)

5、Excellent post-sales service and technical backup

For this project, The Voson engineering team completed commissioning within 6 weeks, including power connection, test runs, and local team training. Operators learned about machine control, maintenance, flour quality control, and packaging efficiency.

FAQ – About Nigeria Maize Flour Mill

Q1: Is a 20TPD maize milling plant suitable for startups in Africa?

Yes. It strikes a balance between output and investment. It’s ideal for local food producers looking to enter the maize flour market.

Q2: Can Voson customize equipment for local maize varieties in West Africa?

Absolutely. Machines are fine-tuned for grain size, moisture, and dehulling behavior specific to each region.

Q3: What is included in Voson’s turnkey solution?

Our service includes layout design, all machinery, shipping, installation, trial run, staff training, and post-sale support.

Conclusion – Small-Scale, High-Efficiency Maize Flour Plant for Africa

Nigeria maize flour mill project proves Voson’s strength in delivering low-investment, high-output maize milling solutions. From Africa to Asia, we continue empowering food producers with reliable grain processing systems.

Ready to build your maize milling plant?

📩 Email: info@grainengineering.com

📱 WhatsApp: +86 186 2554 8111