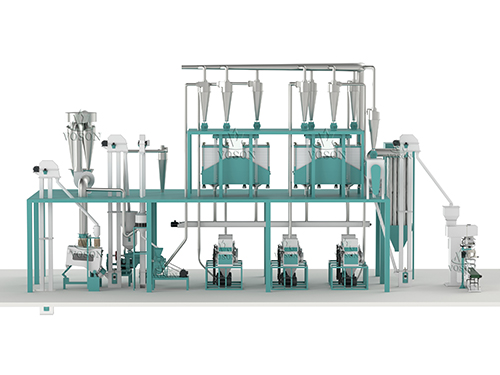

Complete Maize Flour Milling Solution

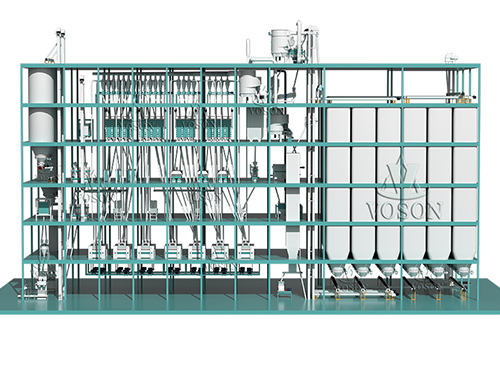

Turnkey Maize Flour Milling Plant for Industrial Corn Flour Production

As the global demand for corn-based food products continues to rise, reliable and efficient maize flour milling solution are critical for food producers. At Voson Machinery, we specialize in delivering turnkey maize milling plants that transform raw maize into high-quality flour through a fully automated and streamlined process.

In this project showcase, we detail the design and implementation of a 50TPD maize flour processing line, highlighting the core technologies, customized layout, and on-site services that ensure long-term performance and profitability.

Why Choose a Complete Maize Flour Milling Solution?

A complete maize milling solution offers more than just machines—it delivers a total grain processing ecosystem optimized for efficiency, yield, and quality.

1、All-in-One System: From maize cleaning and dehulling to grinding and packing, every step is integrated into a continuous line.

2、Improved Product Consistency: The system ensures uniform flour granulation, minimal impurities, and stable output.

3、Energy & Labor Efficiency: Automated control systems and optimal mechanical design reduce energy use and manpower.

Whether for food-grade corn flour, maize meal, or industrial grits, Voson’s tailored solutions meet a wide range of market demands.

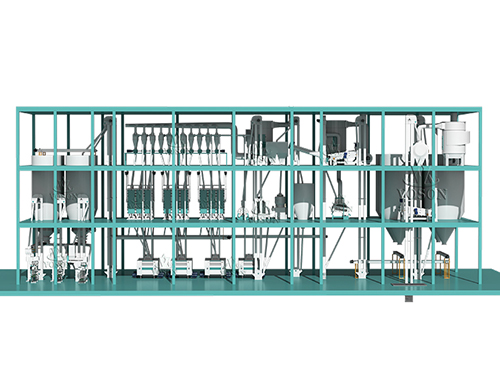

Maize Flour Milling Process Flow

1. Cleaning Section

Raw maize enters the cleaning section, where it passes through:

- Plane rotary vibrating screen for dust removal

- Magnetic separator to remove metal contaminants

- Destoner machine to eliminate stones and heavy impurities

2. Conditioning and Degermination

Moisture is adjusted to optimize dehulling. The maize dehuller and polisher remove bran and germ, increasing flour whiteness and shelf life.

3. Milling and Sieving

Processed kernels are ground in roller mills, and the flour is graded using plansifters. Bran and coarse particles are recycled for re-grinding to increase extraction rate.

4. Blending and Packing

Blending bins allow customized flour mixtures. Final flour is packed with automatic packing machines into 10kg–50kg bags.

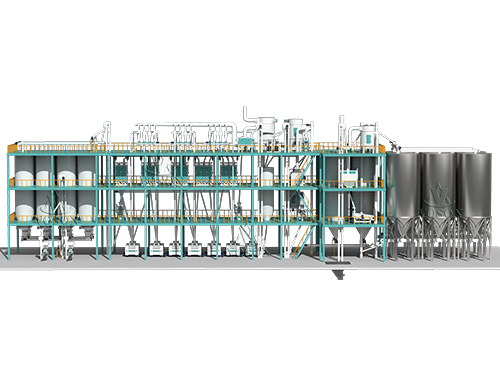

Project Overview: 100TPD Maize Flour Plant in Burkina Faso

Location: Ouagadougou, Burkina Faso

Capacity: 50 tons per day

Output Products: Fine maize flour, maize bran

Application: Local staple food supply, community distribution, school meal programs

Key Client Requirements:

- A cost-effective maize flour milling line for mid-scale production

- Compact design to fit limited factory space

- Stable operation under Burkina Faso’s hot, dry climate

- Easy-to-operate system with minimal labor requirements

Voson’s Solution:

Voson Machinery delivered a 50TPD complete maize flour milling solution, optimized for local conditions and community-level production goals. Our scope included:

- Customized plant layout and process flow tailored to client site

- Full set of maize processing equipment: cleaning, dehulling, milling, sieving, and packing

- Energy-efficient motors and dust control systems to suit local power stability

- Remote and on-site technical support, including operator training

This turnkey maize milling plant was installed and commissioned in just 3 months, and has since operated reliably to meet daily flour demands in Ouagadougou and surrounding areas.

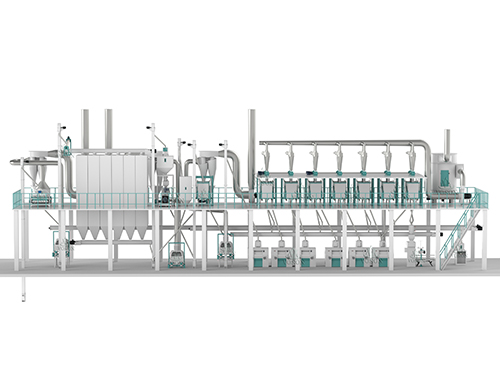

Why Partner with Voson?

- Complete Engineering Support: From design and manufacturing to installation and training

- Flexible Solutions: We offer maize flour milling lines from 10TPD to 500TPD

- Global Experience: Projects completed in 35+ countries across Africa, Asia, and Latin America

- Local Adaptation: Tailored for raw material, power supply, climate, and consumer preferences in your region

Voson is your trusted partner for building a maize flour business from the ground up. Looking to build or upgrade your maize flour milling plant? Let Voson Machinery provide you with a customized maize milling solution designed for your needs and your market.