Powder Grinder Machine for Beans and Grains

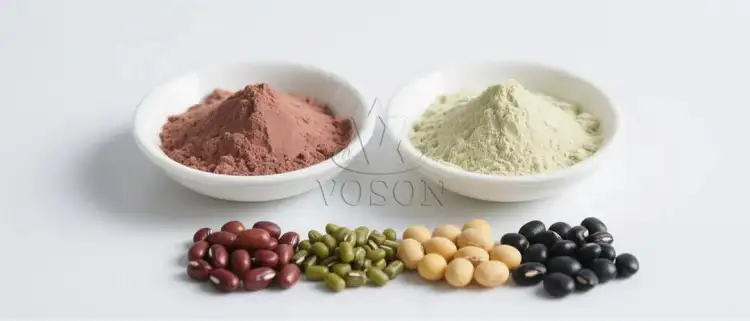

Looking for a reliable solution to produce fine powder from dry grains and legumes? The Voson Powder Grinder Machine is purpose-built for turning ingredients like soybeans, red beans, mung beans, wheat, and corn into consistent, high-quality flour. With a processing range of 100kg/h to 500kg/h, it’s well-suited for small-scale factories, commercial kitchens, and startups in the food manufacturing sector.

Key Features of the Voson Powder Grinder Machine

1、Efficient Bean and Grain Grinding

This powder grinder machine delivers fast and uniform grinding of dry materials such as soybeans, red beans, wheat, and corn. Powered by high-speed rotating blades, it supports continuous operation and delivers consistent output for food and powder processing industries.

2、Wide Application in Powder Production

Suitable for producing fine powders from various raw materials, including pulses, grains, herbs, and spices. Common applications include red bean flour, soybean powder, mung bean powder, and other plant-based flour products.

3、Adjustable Fineness for Powder Milling

Mesh screens with different sizes (60–120 mesh) can be selected to achieve the desired powder fineness, allowing users to meet specific production needs in food processing and dietary supplement manufacturing.

4、Food-Grade Design with Easy Maintenance

All parts in contact with materials are made of stainless steel, ensuring safety and hygiene. The machine is easy to operate, clean, and maintain, making it ideal for daily use in commercial milling applications.

5、Compact Size, Flexible Output Range

With models supporting 100kg/h to 500kg/h, this grinder is suitable for both startups and established facilities seeking a reliable bean and grain flour grinder.

Technical Specifications – Grain & Bean Powder Grinder

| Model | Capacity (kg/h) | Power (kW) | Feeding Size (mm) | Fineness (Mesh) | Dimensions (mm) |

|---|---|---|---|---|---|

| VSG-100 | 100–150 | 3 | ≤15 | 60–120 | 600×500×900 |

| VSG-200 | 200–300 | 5.5 | ≤15 | 60–120 | 750×600×1000 |

| VSG-300 | 300–500 | 7.5 | ≤15 | 60–120 | 850×700×1100 |

Custom designs and extended models are available upon request.

Versatile Applications Across the Food Industry

The Voson powder grinder isn’t just for one type of product—it’s a flexible piece of equipment that adapts to your production needs. It’s commonly used in:

- Bean flour production – such as mung bean, black bean, or soybean powder

- Cereal grain processing – including wheat, corn, barley, buckwheat

- Spice and herbal grinding – like chili powder, dried ginger, turmeric

- Nutritional and meal-replacement powders – blended grains and plant-based ingredients

The machine supports a variety of mesh screen sizes to produce different degrees of powder fineness, typically between 60 and 120 mesh.Get a Free Quote Now

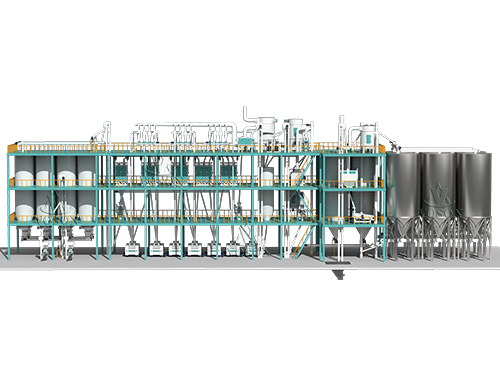

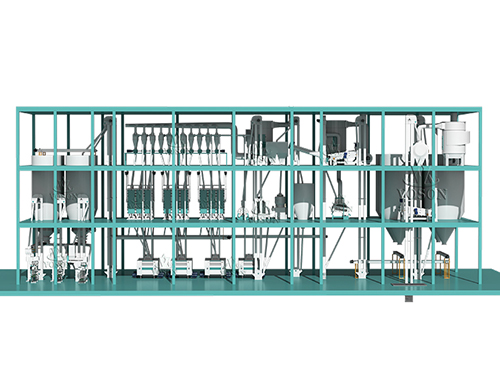

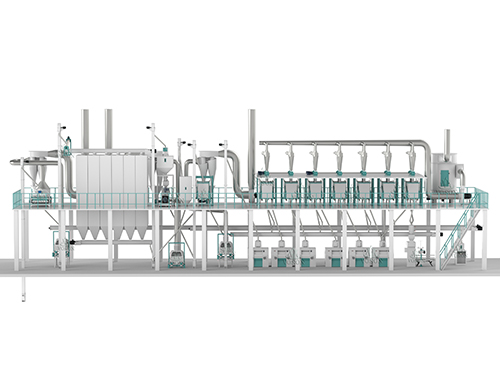

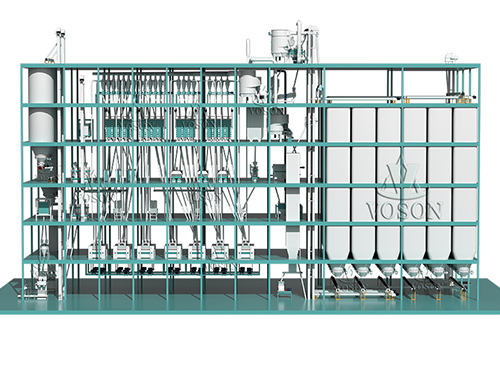

A Turnkey Milling Solution from Voson

Unlike single-machine manufacturers, Voson provides complete grain milling solutions. If your operation requires more than just grinding, we can design and deliver an integrated processing line—from raw material cleaning and dehulling to grinding, sifting, and packaging.

Our powder grinder machines are often part of full-scale flour processing projects, helping food producers around the world streamline their production and maintain consistent product quality.

FAQ

Q1: What materials can be processed with Voson powder grinder machine?

A1: It is suitable for dry beans (like soybeans, mung beans, red beans), cereals (wheat, corn, barley), and dried herbs or spices.

Q2: What mesh sizes are available for powder output?

A2: The machine typically supports mesh sizes from 60 to 120. The screen can be changed based on your desired powder fineness.

Q3: Is the powder grinder easy to clean and maintain?

A3: Yes, the machine features a stainless steel body and an accessible design that allows for daily cleaning with minimal downtime.

Q4: Can it be integrated into a full flour milling line?

A4: Absolutely. Voson offers turnkey solutions, and this grinder can be combined with cleaning, sifting, and packaging units.

Q5: Is customization available for different capacities?

A5: Yes, we provide both standard models and custom solutions depending on your production requirements.Get a Free Quote Now