Turnkey Flour Mill Project | Complete Wheat & Maize Milling Plant Solutions

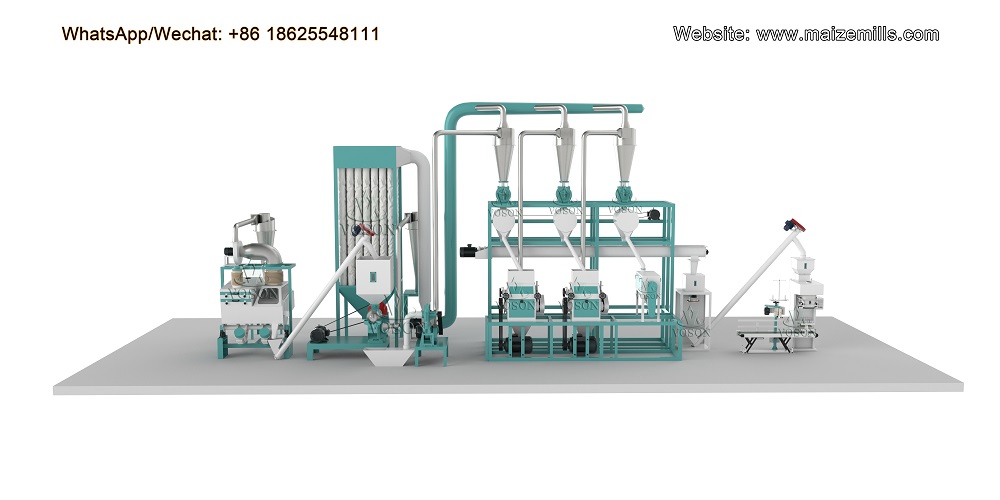

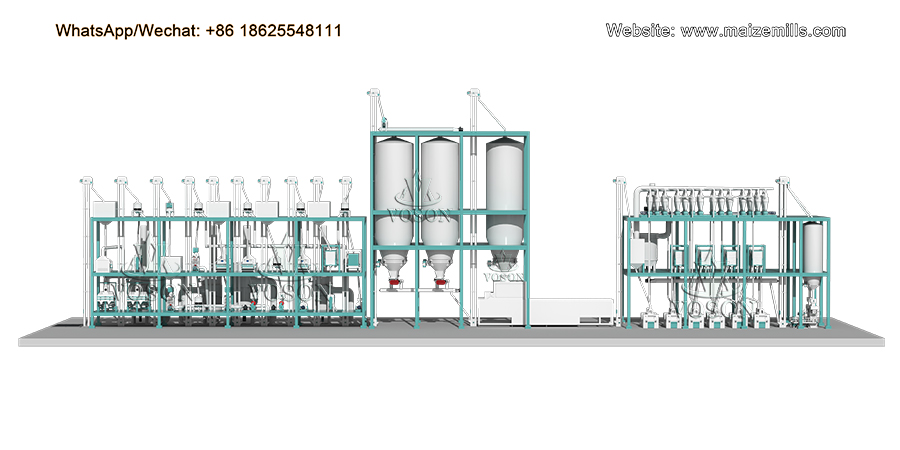

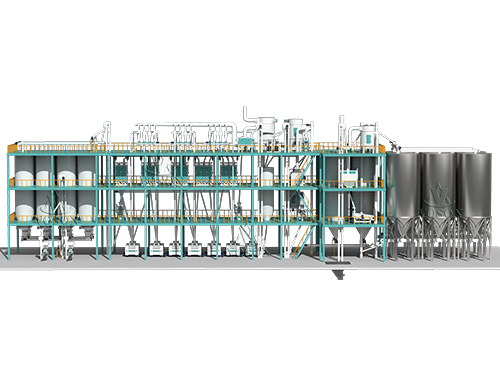

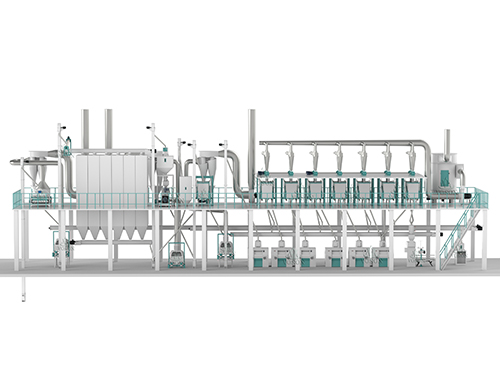

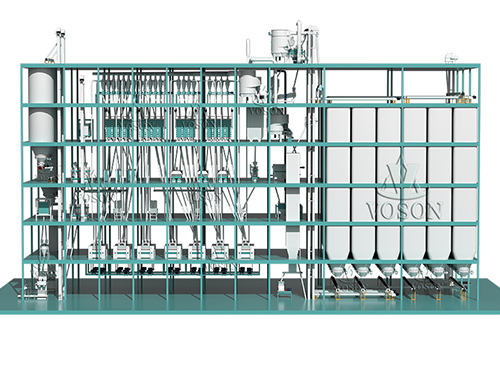

Are you planning to build a flour milling plant but unsure where to start? At Voson, we specialize in turnkey flour mill project, offering fully customized engineering services for wheat and maize flour processing plants. From feasibility study, design, manufacturing, and installation to final commissioning—we deliver complete solutions tailored to your local market and grain types.

Whether it’s a 50TPD wheat flour plant in Africa or a 200TPD maize milling project in Latin America, our team ensures that each project is delivered on time, on budget, and above expectation.

What Does a Turnkey Flour Milling Project Include?

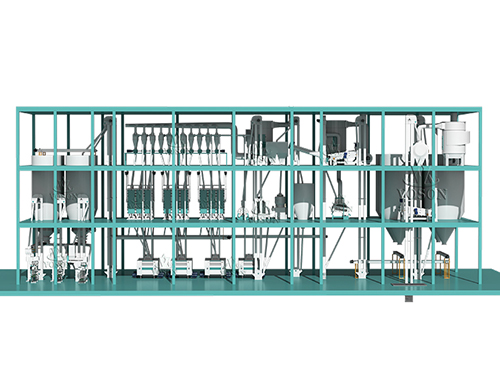

A turnkey flour milling project from Voson is more than just equipment delivery—it is a complete, end-to-end solution built to meet the specific requirements of your market, your raw materials, and your site conditions. Our scope of supply typically includes:

1、Feasibility study and technical consultation, helping you define production capacity, raw material types, and utility needs

2、Custom plant layout and process flow design, optimized for wheat, maize, or a combination of both

3、Full set of processing equipment, including cleaning, conditioning, milling, sieving, blending, and packing systems

4、Automation and control systems, from semi-automatic to PLC-based full automation

5、Steel structure or civil engineering coordination, based on local site conditions

6、On-site installation guidance and commissioning, ensuring operational reliability from day one

7、Training of operators and maintenance teams, enabling independent, sustainable plant operation

With our turnkey approach, you can avoid the typical delays and miscommunications caused by managing multiple vendors and contractors. Instead, you benefit from centralized project control, standardized quality, and coordinated execution across every stage of development.

Flour Milling Plant Overview

Our engineering team designs flexible flour mill solutions for both wheat flour and maize meal production. Though the basic process steps are similar, each grain has unique requirements.

| Process Stage | Wheat Milling Process | Maize Milling Process |

|---|---|---|

| 1. Cleaning | Vibrating screen, destoner, magnetic separator | Rotary cleaner, gravity separator |

| 2. Conditioning | Moisture adjustment for better bran separation and milling efficiency | Not required (maize goes directly into degermination after cleaning) |

| 3. Degermination | Not applicable | Removal of germ and bran for high-quality, refined maize flour |

| 4. Milling / Grinding | Roller mills, plansifters, purifiers | Hammer mills or roller mills, depending on desired flour texture |

| 5. Sieving & Grading | Integrated with plansifters and purifiers | Fine sieving and grading to classify final product types |

| 6. Flour Blending | Flour blending system for consistency and quality control | Optional, depending on market needs |

| 7. Packing | Automated packing system | Automated packing system |

We also support dual-line plants that process both wheat and maize, offering maximum flexibility with shared infrastructure.

Typical Turnkey Project Cases

| Location | Raw Material | Capacity | Project Highlights |

|---|---|---|---|

| Burundi | Maize (corn) | 100 TPD | Full maize flour production line with cleaning, degermination, grinding, and packaging |

| Kazakhstan | Wheat | 5 TPD | Compact flour milling unit designed for local bakery supply with minimal footprint |

| Burkina Faso | Maize | 50 TPD | Dual-product plant producing both maize meal and grits with high extraction efficiency |

| Uganda | Maize | 10 TPD | Cost-effective small-scale plant with integrated cleaning and hammer milling systems |

Need a project tailored to your country or grain type? Contact Us Today

What Affects Flour Mill Project Cost?

1、Production capacity (e.g. 30TPD vs 300TPD)

2、Raw material type (wheat, maize, or both)

3、Level of automation

4、Construction and shipping costs

5、Utility requirements: electricity, water, etc.

We offer transparent budgeting with itemized cost breakdown and guaranteed timeline.

Frequently Asked Questions (FAQ)

Q1: How long does it take to complete a turnkey flour mill project?

Depending on plant capacity and location, most projects take between 3 to 5 months from contract signing to operational commissioning.

Q2: Can I process both wheat and maize in one facility?

Yes, we provide flexible dual-line designs that accommodate both grains with minimal equipment duplication.

Q3: What is the minimum capacity Voson can provide?

We offer solutions starting from 20TPD for small-scale operations up to 500TPD for industrial producers.

Q4: Is operator training included?

Absolutely. On-site training and detailed technical manuals are standard parts of every turnkey delivery.

Q5: How much does a complete flour mill project cost?

Contact us with your desired capacity and grain type for a tailored quote. Prices vary widely based on specifications.

Get Started with Voson—Your Reliable Partner for Flour Mill Projects

As one of the leading manufacturers and engineering providers in China’s grain processing industry, Henan Voson Grain Engineering Machinery Co., Ltd. has the expertise, equipment, and experience to bring your flour milling vision to life. Whether you’re looking to enter the market with a compact mill or expand into turnkey flour mill project, our turnkey services give you a solid foundation for long-term success.

📧 Email: info@grainengineering.com

📞 WhatsApp: +86 186 2554 8111

🌐 Contact us today to discuss your project and receive a personalized solution.

Let Voson help you turn your grain into value—with precision, professionalism, and partnership.