How to Choose a Reliable Flour Milling Equipment Supplier

Choosing the right flour milling equipment supplier is one of the most important decisions for investors who plan to build or upgrade a flour mill. A reliable supplier can provide stable equipment quality, complete technical support, and long-term spare parts service. On the contrary, choosing the wrong supplier may lead to high operating costs, frequent breakdowns, and unstable flour quality.

This guide explains how to evaluate a flour milling equipment supplier and why many global customers choose Voson as their long-term milling machinery partner.

Evaluate the Supplier’s Experience in Flour Milling Industry

Industry experience directly affects equipment stability, process design accuracy, and project execution capability. A reliable supplier should have long-term involvement in wheat milling, corn milling, and other grain processing industries, as well as successful projects across different countries.

Experienced suppliers can:

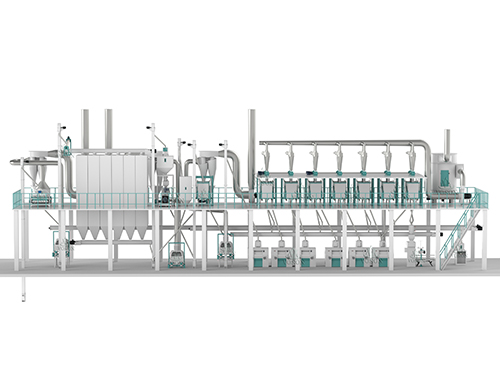

- Provide mature process solutions for various capacities from small 20–50TPD to large 100–300TPD mills.

- Understand local grain characteristics and customize flow charts accordingly.

- Offer stable and verified machinery models for continuous operation.

Voson Advantage:

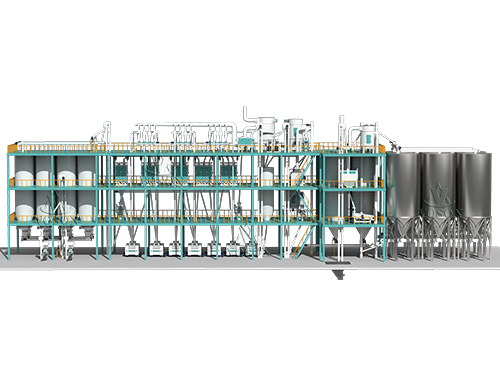

Voson has decades of experience in providing flour milling equipment, turnkey solutions, and overseas engineering services. Our equipment is used in Africa, Asia, South America, and Eastern Europe, covering wheat flour mills, corn mills, and multifunction grain processing lines.

Check the Quality and Standardization of Core Milling Machinery

Core equipment determines the operation quality of the whole flour mill plant. A trustworthy supplier must provide machines with stable operation, high precision, and long service life.

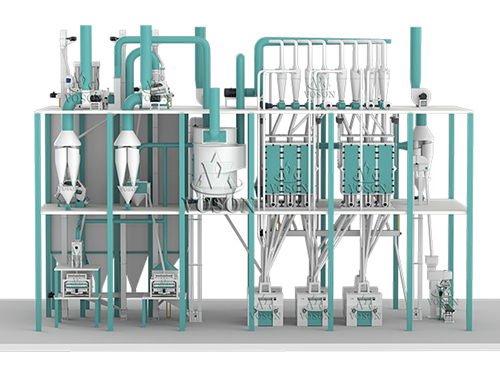

Key machines you should examine include:

- Roller Mills – smooth running, precise feeding, uniform grinding

- Plansifters / Double or Single Body Sifters – stable separation, high efficiency

- Pneumatic or Manual Control Roller Mills – depending on automation level

- Cleaning Equipment – destoners, vibrating separators, scourers, dampeners

- Blowers, Cyclones, Conveying Systems – ensure stable air circulation

- Packing Machines – consistent and accurate final output

Voson Advantage:

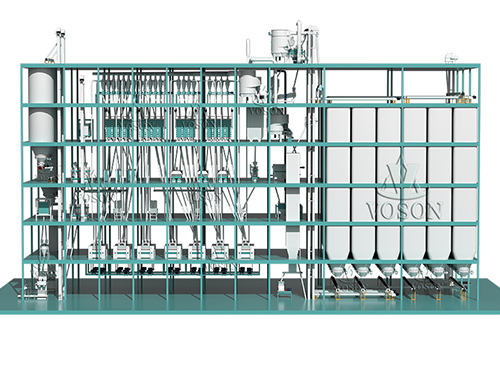

Voson provides a complete range of wheat milling machines, corn milling machines, plansifters, pneumatic roller mills, grain cleaning equipment, and fully customized flour mill plant solutions from 20TPD to 300TPD. All mechanical parts are produced under strict quality control, ensuring high yield and stable operation.

Confirm the Supplier’s Capability for Turnkey Flour Mill Projects

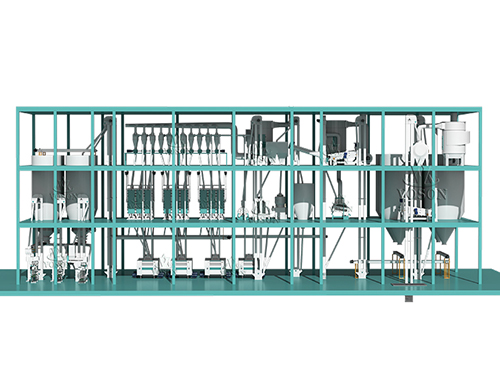

Modern flour mills require more than individual machines. A reliable supplier should be able to offer integrated services, including:

- Design of complete flour milling line

- Process engineering and layout drawing

- Equipment manufacturing and quality inspection

- Installation and commissioning

- Operator training and long-term technical support

Voson Advantage:

Voson specializes in turnkey flour mill solutions, covering engineering design, production, installation, on-site training, and after-sales service. Our team has extensive overseas project experience, especially in Africa and Asia

Evaluate the Supplier’s R&D and Technology Capabilities

Advanced and well-researched equipment brings higher flour yield, lower energy consumption, and better product quality. You should check:

- Whether the supplier updates machine designs regularly

- Whether pneumatic systems, roller structures, and sifter frames follow modern engineering principles

- Whether the plant layout meets current energy-saving and sanitation standards

Voson Advantage:

Voson continuously upgrades roller mill structures, plansifter frames, and cleaning systems to improve efficiency and reduce operational cost. Our pneumatic roller mill and new-generation plansifter are widely adopted by customers seeking higher performance in modern milling lines.

Check Real Project Cases and Customer Feedback

Seeing real installations is one of the most convincing ways to judge a supplier’s reliability. Look for:

- Flour mill projects in your target region

- Long-term running reports

- Customer feedback and repeat orders

- Countries where the supplier has engineering experience

Voson Advantage:

Voson has completed numerous flour mill projects, including 20TPD, 50TPD, 80TPD, 100TPD and large custom solutions. Many customers return to us for plant expansion or upgrading of equipment, demonstrating high recognition of our product quality and technical support.

Compare Price vs. Value – Not Just the Initial Cost

The cheapest milling equipment often means:

- lower-quality steel

- unstable machines

- poor flour output

- high failure rate

Instead of choosing the lowest price, customers should choose suppliers who provide reasonable pricing with stable reliability.

Voson offers direct factory prices and ensures the best balance between cost and performance, which is why many customers choose Voson to upgrade old mills.

Why Many Investors Choose Voson as Their Flour Milling Equipment Supplier

Many investors choose Voson because the company offers professional engineering capability, complete wheat and corn milling solutions, strong manufacturing capacity, and reliable turnkey project services. Voson focuses on stable machine performance and long-term technical support, helping customers reduce operational risks and achieve higher production efficiency.

As an international supplier, Voson provides full-language technical service, including English, Russian, Spanish, French, and more, making communication easier for global clients. With rich export experience and engineering cases in multiple countries, Voson ensures smooth project delivery from factory design to installation and commissioning.

Today, Voson has become a trusted partner for investors who plan to build new flour milling plants or upgrade existing facilities. No matter the scale of the project, Voson can deliver efficient, cost-effective, and fully customized milling solutions.

For inquiries, you may contact: info@grainengineering.com / WhatsApp +86 186 2554 8111.