Top Mistakes to Avoid When Purchasing Grain Milling Machinery

Investing in grain milling machinery is a major decision for mill owners, entrepreneurs, and investors. Whether you are planning a new milling project or expanding an existing facility, choosing the wrong equipment—or the wrong supplier—can lead to high operating costs, frequent breakdowns, and unstable product quality. To help buyers make smarter decisions, we have summarized the most common mistakes investors should avoid when purchasing grain milling machinery.

Ignoring the Real Capacity Requirements

One of the biggest mistakes buyers make is selecting machinery that does not match their production goals. Choosing a line that is too small limits future business growth, while an oversized system wastes money and increases operating costs.

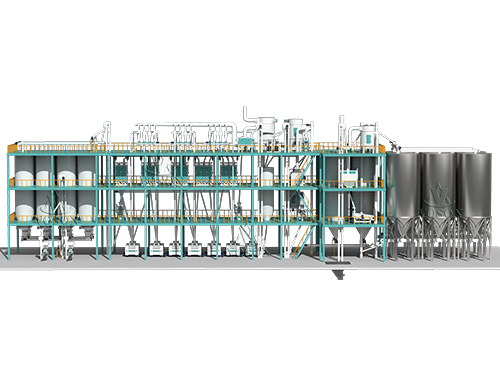

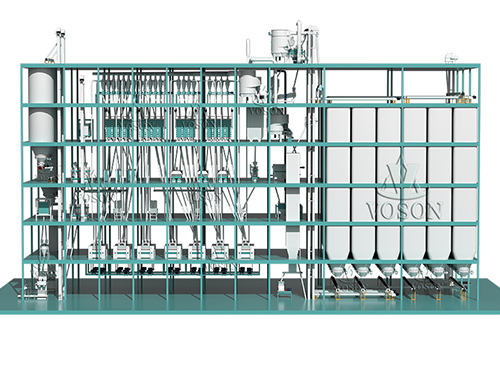

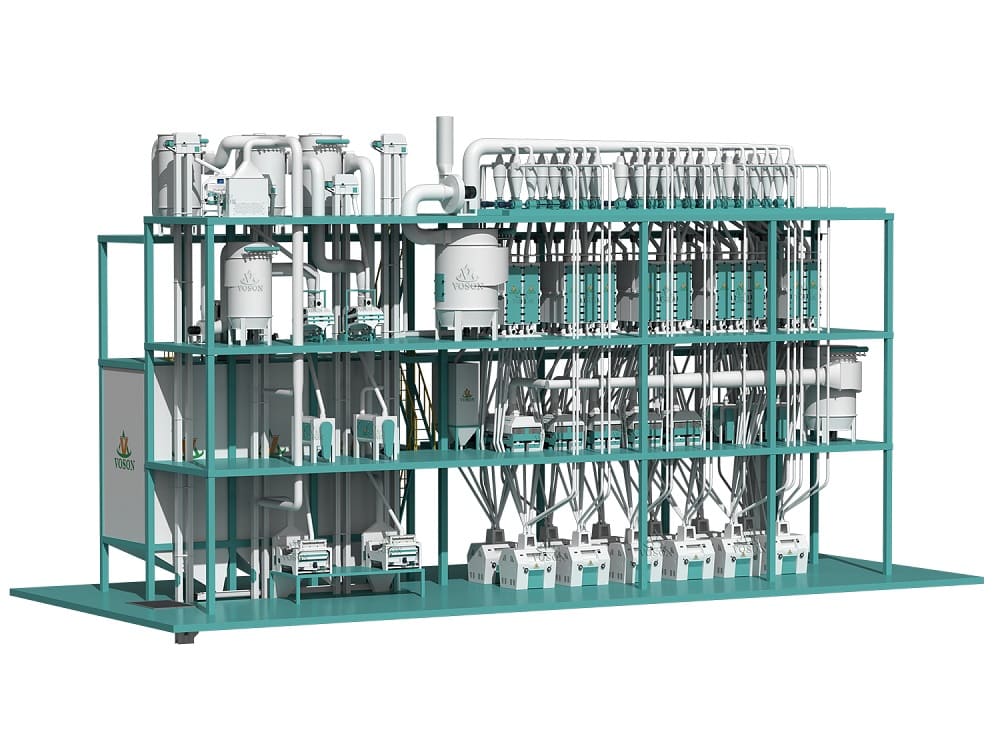

Reliable suppliers like Voson provide tailored solutions ranging from 20TPD to 500TPD for wheat and corn milling, ensuring the equipment perfectly matches your production strategy.

Focusing Only on Price Instead of Cost Performance

Low-price machinery often leads to higher long-term expenses due to frequent maintenance, lower yield, and unstable running.

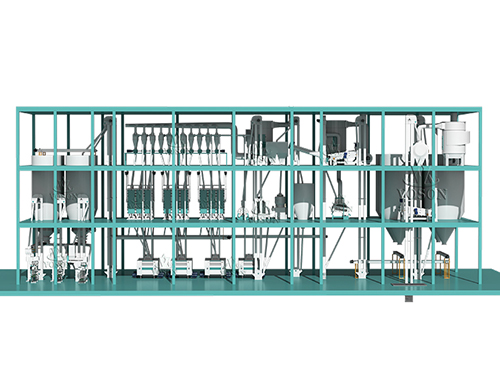

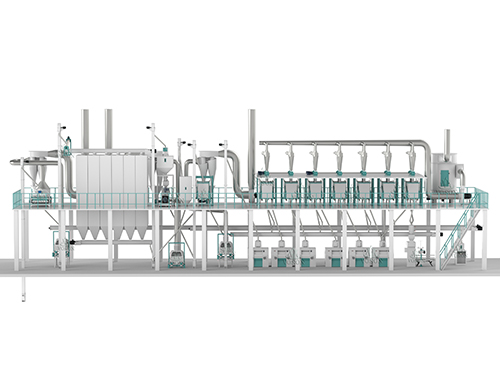

Quality grain milling machines—such as roller mills, pneumatic roller mills, plansifters, purifiers, destoners, and vibrating cleaners—require precision manufacturing. Voson uses stable structures, high-grade materials, and reliable components to ensure long service life and consistent output.

A slightly higher initial investment often results in significantly lower operating costs.

Not Verifying the Supplier’s Engineering Experience

Many investors only look at product brochures but ignore the supplier’s engineering capability. A reputable supplier must provide:

- Factory layout design

- Process flow optimization

- Installation and commissioning

- Training and long-term support

Voson’s engineering team has rich experience in wheat milling, corn milling, and turnkey milling projects, giving customers reliable guidance from plan to operation.

Choosing Equipment That Is Not Compatible as a System

Some buyers purchase machines from different sources, assuming they can be assembled into a line. However, mismatched machinery often causes:

- Unstable production

- Excessive energy consumption

- Low milling yield

- Frequent troubleshooting

Voson provides complete grain milling lines, ensuring all machines—from cleaners to roller mills to sifters—work smoothly as a unified system.

Overlooking After-Sales Service and Technical Support

Even the best milling machinery requires technical support. A lack of after-sales service results in long downtime and significant losses.

Voson provides ongoing support, including remote guidance, on-site service, maintenance instructions, and spare parts supply, ensuring your milling plant maintains stable performance year after year.

Not Considering Maintenance and After-Sales Service

Many buyers choose suppliers who cannot offer professional after-sales support. When problems occur—bearing issues, sifter imbalance, yield drop, or roller wear—they struggle to find timely solutions.

Voson offers long-term technical support, remote guidance, spare parts supply, and multilingual communication including English, Russian, Spanish, and French, ensuring global customers receive consistent service.

Failing to Verify Actual Project Experience

Some companies have no real project cases but borrow photos from other manufacturers. A trustworthy supplier should have:

- Real plant photos

- Installation site images

- Customer running feedback

- Export experience to multiple regions

Voson has delivered milling equipment to many countries, like Uganda, Burundi, Ethiopia, Kenya, helping investors build reliable and profitable flour milling plants worldwide.

Not Considering Energy Efficiency

Energy cost is a major part of milling production. Machines that consume too much electricity will significantly increase daily expenses.

Voson focuses on energy-efficient grain milling machinery, helping investors reduce operational costs without compromising performance.

Conclusion

Avoiding these common mistakes will help investors choose the right grain milling machinery and build a long-lasting, profitable milling plant. With strong engineering capabilities, complete equipment sets, and turnkey services, Voson remains a trusted partner for investors planning wheat or corn milling projects.

For professional assistance or equipment quotations:

Email: info@grainengineering.com

WhatsApp: +86 186 2554 8111